Smart office life with robots of Hyundai Motor Group

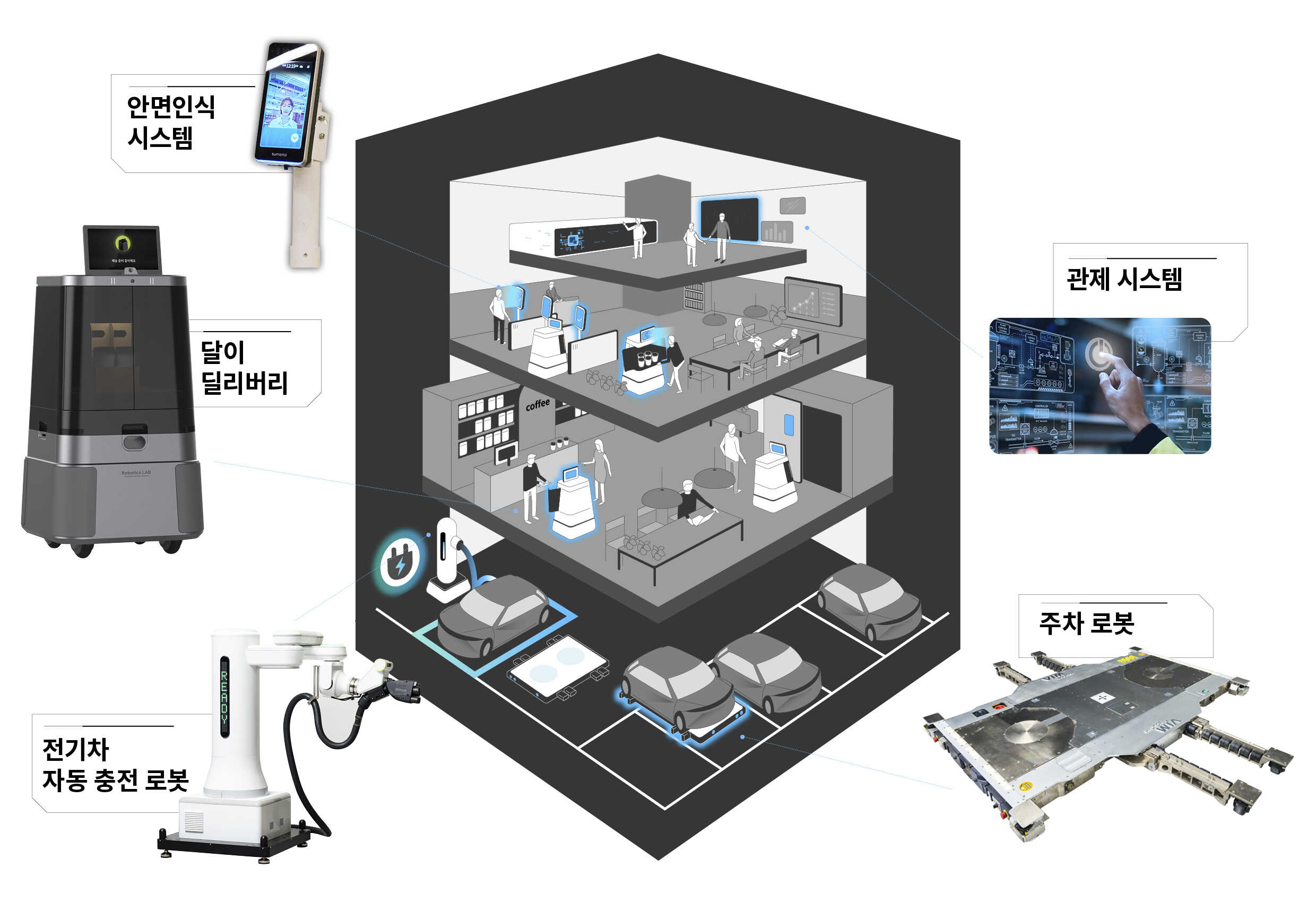

Hyundai Motor Group has introduced a robotics technology-intensive service through a robot-friendly building located in Seongsu-dong, Seoul. We looked at the robot-friendly building, Factory Seongsu, to see what the future of office life will be like with robots completed with advanced technology.

▶ Delivery robot that helps you immerse yourself in your work

▶ Robots that replace parking and charging electric vehicles

▶ Smart office with AI Face Identification

▶ Brain of Robot-Friendly Building

Can robots deliver and manage parking?

Collaboration of human and robot is no longer a distant future story. Robots that help humans are already around our lives. Robot vacuum cleaners that replace cleaning, animal robots that communicate with humans, and serving robots that carry food in restaurants are typical. Such robot technology is widely developed in various fields.

Hyundai Motor Group is also taking preemptive action by operating Robotics LAB that quickly detects the potential of the robot industry and specializes in robotics technology. Thanks to this, Hyundai Motor Group's Robotics LAB is showing a clear presence by introducing various robotics technologies in global robotics industries, including wearable robots, automatic charging robots for electric vehicles and delivery robots. On June 20th, we were able to check the Robotics LAB’s advanced robotics technologies in earnest at the office building located in Seongsu-dong.

Robotics LAB is planning to develop a robotics total solution that can improve user convenience in conjunction with building infrastructure and build solutions in major hubs such as offices and shopping malls. Its first partner is IGIS Asset Management. Through a business agreement in May 2023, the company took the first step in its robot-friendly building business. It learned how Robotics LAB applied the delivery robot and auto charging robot developed for smart business life of residents.

Delivery robot that helps you immerse yourself in your work

The robots of the robotics total solution developed by Robotics LAB have different tasks, but the goal of enhancing the convenience of people working in buildings is the same. Among these robots, DAL-e Delivery is expected to greatly help residents in their work environment. DAL-e Delivery improves their work by reducing unnecessary movement of everyone using the infrastructure. It provides an environment where you can concentrate.

How does DAL-e Delivery help those who work in smart office buildings? The main tasks of DAL-e Delivery are food&beverage delivery and parcel delivery. DAL-e Delivery delivers food and beverages ordered through a dedicated application and deliver parcels in the delivery room, reducing the inconvenience of having to travel during working hours.

DAL-e Delivery: Delivering drinks across the building

To this end, DAL-e Delivery has a large loading space and excellent mobility. DAL-e Delivery can load up to 10kg of goods in the inner space and can accommodate up to 16 cups of coffee. Once the delivery items arrive at the recipient, the authentication is carried out through AI Face Identification. Once the authentication is complete, the door opens on both sides and the tray pushes out to make it easier for the recipient to take out the delivered item. Thanks to the service, residents will be able to concentrate on their work without moving to pick up food and beverages or parcels. The delivery service of DAL-e Delivery will begin on June 20th, and parcel delivery will be available from the second half of this year.

DAL-e Delivery has a large interior space, but the overall size is compact. It aims to minimize the space occupied when moving inside a building or boarding an elevator and to be as compact as possible to facilitate movement. It also has a minimal round square design that widens downward as the center of gravity decreases.

DAL-e Delivery boasts stable driving with a combination of a low center of gravity structure and plug and drive (PnD) module mounted at the bottom. It is also linked to an elevator and door control system, allowing the robot to travel the entire building. Based on real-time route generation technology, it increases delivery efficiency by moving along the optimal route.

As the main purpose of DAL-e Delivery is to deliver items, 'mobility' is the most important part. The PnD module is responsible for such mobility. The PnD module is the first mobility solution that Robotics LAB unveiled at CES 2022. It is an integrated module that combines in-wheel motors, steering, suspension, brakes and environmental cognitive sensors into one structure and has been developed to give mobility to various objects. DAL-e delivery implements holonomic driving through four PnD modules. Holonomic turn technology is a technology that intentionally rotates a large radius when passing corners to secure a wide viewing angle and help stable driving.

DAL-e delivery uses the holonomic turn technology to safely and quickly deliver the items to the destination by maintaining the driving speed while avoiding collisions and sudden encounters with people. It is designed to rotate 360° and enhance suspension performance so that delivery items are not shaken or damaged. The technology contained in the PnD module is highly expected to play an important role in the future mobility world drawn by Hyundai Motor Group.

Since 2022, Robotics LAB has been conducting demonstration operations of delivery robots at the Gwanggyo Alliway residential and commercial complex and the Rolling Hills Hotel in Hwaseong. Through these demonstration tests, it acquired various data and applied the enhanced functions to DAL-e Delivery. Major improvements include improved driving efficiency and stability through improved PnD module performance, and increased usability through tray discharge structures and minimizing space occupancy. In addition, the software function has been improved so that immediate action can be taken when network issues or other problems occur. In the future, Robotics LAB plans to quickly improve issues arising from delivery robots and gradually expand service areas such as charging, preservation, and guidance as well as delivery.

Robots that replace parking and charging electric vehicles

Workers who commute by car have many things to consider. It is basic to overcome the congested road, and they also have to pay for the fuel costs. The biggest problem is parking. If there is not enough parking space at work, they have to waste a considerable amount of time every day. Hyundai Motor Group has come up with a smart solution to the parking problem. It is the parking robot.

Parking Robot: Let robots handle your parking

First, the automated vehicle transportation robot (hereinafter referred to as parking robot) is a parking robot solution developed by Hyundai WIA for an unmanned smart parking lot. When a driver enters a parking lot and gets out of the vehicle, the parking robot that detects it moves the vehicle directly and proceeds with parking instead. Also, the vehicle is taken out of the parking space and delivered to the owner of the vehicle leaving the building. The automated parking service of the parking robot is expected to help solve the hassle of looking for the parking area.

The parking robot can carry vehicles weighing up to 2.2 tons and its maximum speed is 1.2 m/s. Two parking robots using the tire lift method are located in the middle of the front and rear wheels, one each, and after accurately recognizing the size and position of the wheels through the LiDAR sensor, the vehicle is lifted and moved. Thanks to the precise measurement performance of the LiDAR sensor, it can respond to various vehicles.

As the parking robot enters the lower part of the vehicle, it is designed at the optimal height through miniaturization and ultra-thin instrument structure design. The parking robot recognizes the wheels of the vehicle, enters the lower part, lifts the vehicle, and scans the QR code on the floor to correct the position and posture. At this time, through real-time synchronization the two robots move in the front, rear, left, and right directions as if they are one.

The smart parking control system of Hyundai Wia is in charge of the parking status and the real-time movement of the parking robot. In this control system, overall control such as vehicle placement, optimal route algorithm, robot condition monitoring, and traffic control between parking robots are performed, and up to 50 parking robots can be simultaneously controlled.

Hyundai Motor Group has built an integrated solution that combines an auto charging robot with a parking robot in the robot-friendly building. ACR is an auto charging robot developed by Robotics LAB. ACR enhances the convenience of charging electric vehicles. It can insert charging cables with electric vehicles and remove cables when charging is completed, which is why it is a fully automated system that can be used by the mobility handicapped. ACR can be found in a shared vehicle service that can be used by residents of robot friendly building and will be operated in earnest from the third quarter of this year.

Automatic Charging Robot: Providing EV charging service

ACR is linked to the parking robot and operates after the customer uses the shared vehicle and returns the vehicle. When the parking robot moves the vehicle to the charging area, ACR recognizes the license plate and checks the charging amount of the vehicle. If charging is required, ACR opens the charging port of the vehicle through wireless communication and inserts the charger. ACR also removes the charger after charging is completed, so the user does not have to be involved at all. In other words, customers who use the shared vehicle service do not have to pay attention to parking and charging after returning the vehicle, so they can enjoy high convenience.

Hyundai Motor Group aims to provide robot friendly building occupants with a state-of-the-art parking experience through an integrated solution consisting of a parking robot and ACR that has never been seen anywhere. The solution includes Hyundai Motor Group's efforts to solve the parking problem through smart robotics technology, which is considered one of the problems of modern society. Hyundai Motor Group will continue to try to break the prejudice that parking is bothersome and inconvenient by gradually expanding the parking solution of the robot friendly building in the future.

Smart office with AI Face Identification

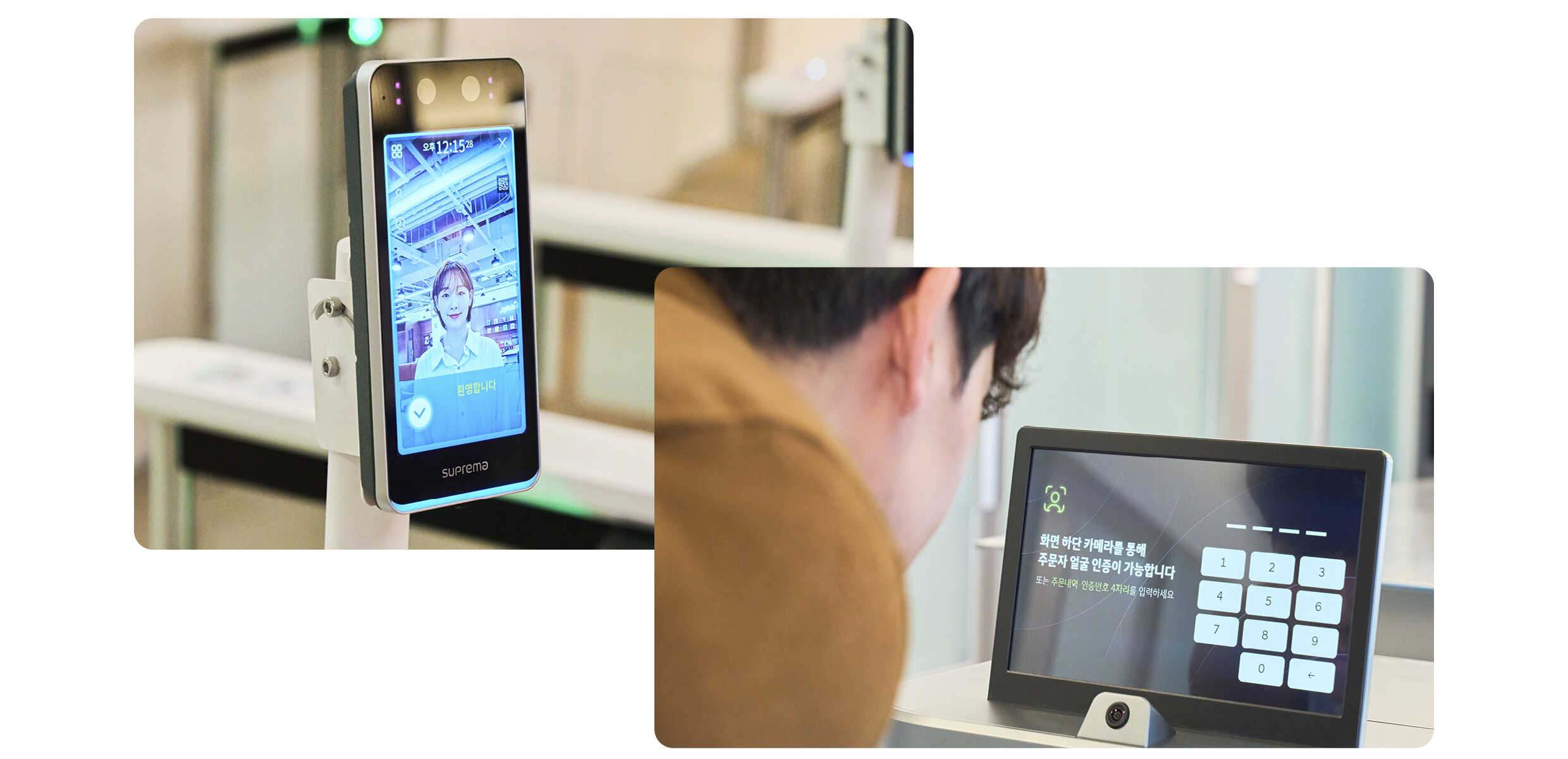

Employee ID cards take over the role of identification cards in the company. They are used to enter a workplace or to verify that one belongs to a company. Employee ID card is an important item and must be kept when working, but when you go to work, you may forget it at home or lose it. Robotics Total Solution provided by Robotics LAB introduces cutting-edge AI Face Identification technology that replaces employee IDs in buildings, which reduces the inconvenience of having to take out employee IDs to authenticate yourself and check them.

AI Face Identification technology: Equipped with 99.9% accuracy

Robotics LAB has developed various algorithms to complete AI Face Identification technology. Facial detection algorithm to detect facial areas, facial recognition algorithm to extract feature points of the face and lastly, facial attribute algorithm that determines age, gender, and whether one wears a mask or not.

In addition, it has completed a system by developing an anti-spoof function that prevents images or videos from being recognized instead of real faces and an AI lightweight technology to complete the system for real-time operation and recognition in 0.1 seconds. The completed algorithm has been certified by the Korea Internet & Security Agency (KISA) and secured reliability by recording a high figure of 99.98% (error rate 0%).

Robotics LAB is linking facial recognition solutions to access terminals and robot services. The facial recognition function has been applied to staircases, lobbies, workspaces, parking lots, security gates and some other places in buildings to enhance the convenience of moving between spaces. Through this function, any employee of the company in the office building can authenticate himself or herself with this technology. Even when receiving items delivered by DAL-e Delivery, the recipient can authenticate himself or herself with AI Face Identification. In the future, AI Face Identification technology will be further advanced and applied to other robots.

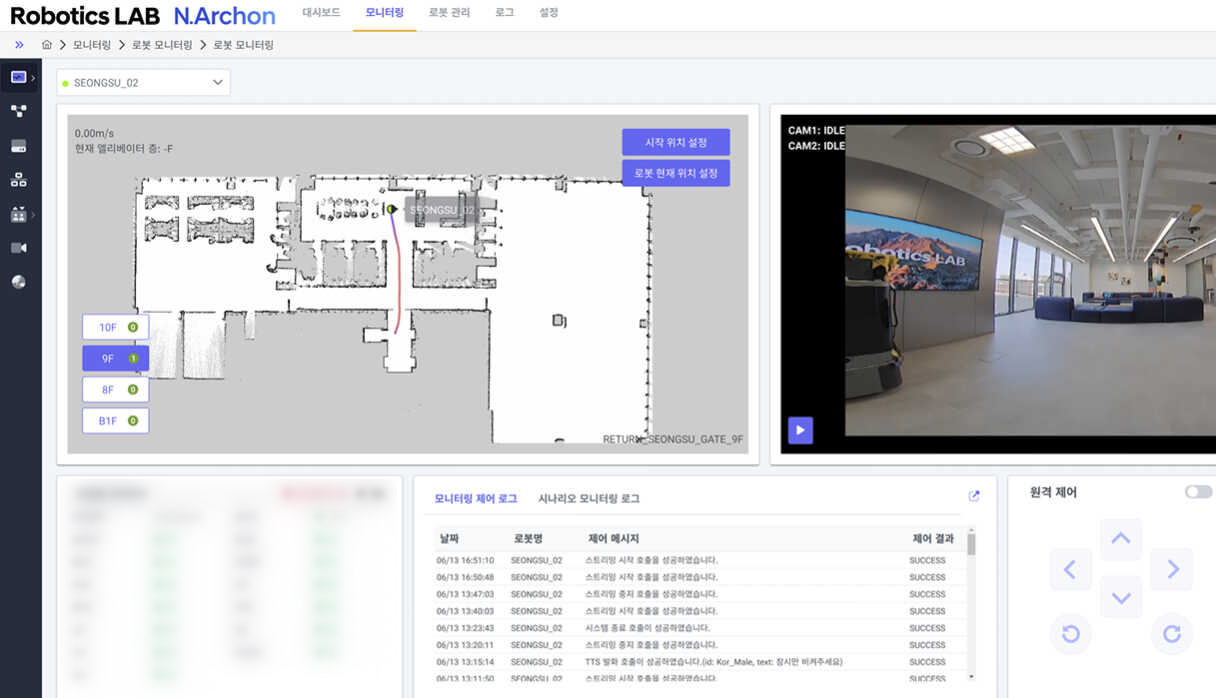

Brain of Robot Friendly Building

Hyundai Motor Group is trying to introduce a new office life through robot-friendly buildings. To that end, it has developed various robotics technologies related to delivery, security, mobility, and has begun a meaningful first challenge by applying them in earnest to Seongsu Factorial. However, control system is essential to take action when robot has issues or upgrades new services.

Robotics LAB aims to increase the convenience of operating and managing robots in buildings by developing a control system applied to robots. The fleet management system developed by the cloud-based Software as a Service (SaaS) comprehensively controls and manages various robots developed by Robotics LAB. Hyundai Motor Group will acquire robot management data through its operation at Seongsu and will manage robots by applying more advanced control system when expanding related businesses in the future.

The future of human beings and robots has already begun. Starting with this smart office building, Hyundai Motor Group plans to expand its robotics total solutions to various buildings located at key business hubs in Korea. We will also establish and expand the standard of robotics services from the perspective of consumers in order to enhance the service satisfaction of companies in the building. Such efforts will serve as a foundation for the technological development and the development of the robot industry in Korea. Hyundai Motor Group will continue to develop related technologies to realize a society where humans and robots coexist, which we vaguely imagined.

Photo by Min Young (민영영)

KEYWORD